There are numerous sorts of oil. We have the liquid film oil, “elastohydrodynamic” oil (E.H.L.) and limit oil. Each has their own one of a kind property and techniques in giving backing to a designing material, normally direction or 2 surfaces that require developments yet in contact with each other (rub each other).

In liquid film grease, the moving surfaces are totally isolated by a separation. This separation is loaded with a film of a fluid or vaporous oil sort. At that point, a heap supporting weight is created by one of the accompanying sorts of oil; ‘hydrodynamic grease‘, crushes film activity and remotely pressurized activity.

For the ‘hydrodynamic grease’ (H.L.), the film isolating the liquid is being drawn into a focalizing, wedge molded zone by the self acting pumping of the moving surface. Both the weight and frictional force misfortune in this film serve as elements of the thickness of grease, in blend with the geometry and shear rate forced by the specific bearing working conditions.

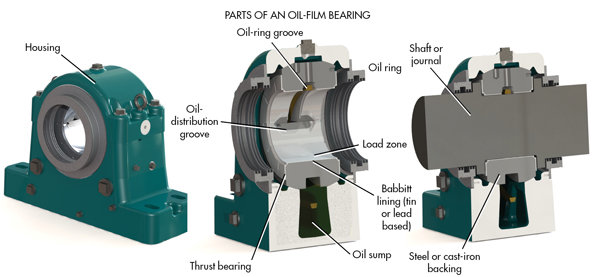

Hydrodynamic heading are regularly sorted as sleeve course (or diary direction) and push orientation (compressive sort course). For the previous, the diary bearing encompasses its mating diary surface on the pole of a machine as an outspread bearing. With respect to the last mentioned, the push bearing, there exists an oil film at the substance of a pole shoulder or neckline for area and pivotal backing of a rotor.

Despite the fact that oils of such give extraordinary backing and diminished costs, the heap limit is regularly not that high, when contrasted with different sorts of heading utilized. A hydrodynamic bearing is a direction sort. Out of the numerous bearing sorts, it rides on a film of liquid, rather than obliging surfaces to be in contact (mating). This specific liquid can be in gas or fluid structure. The way a hydrodynamic bearing works is by relying upon its geometry. Its geometry demonstration to make stream and weight in the liquid. At that point, it is this liquid weight that conveys the real load connected, and subsequently, no metal to metal contact happens. Thickness of this liquid film under the pole is slim. This influences the way that the bearing surfaces should likewise be smooth.

Diary direction is a hydrodynamic bearing sort. The diary bearing is generally depicted as a round and hollow shaft in a tube shaped neckline, with a freedom crevice C loaded with an ointment between these two. At that point, when a heap is set on the pole, the pole gets off kilter. Presently, it is said that the hole under the pole is little than the prior unique leeway. Note that the pole is not touching the surface of the barrel shaped neckline surface, as this is a hydrodynamic bearing. Grease particles adhere to the pole and are maneuvered into the narrowing crevice. This causes liquid weight under the heap to rise and keeping an oil film between the pole and neckline.